Tooling repair and maintenance to keep your investment in top shape

When your tool room is backed up, call us. We evaluate the best way to solve your problem quickly and give you an honest assessment of the issue. We can update your math models to reflect any modifications or revision-level changes so you are always up to date with your 3D data.

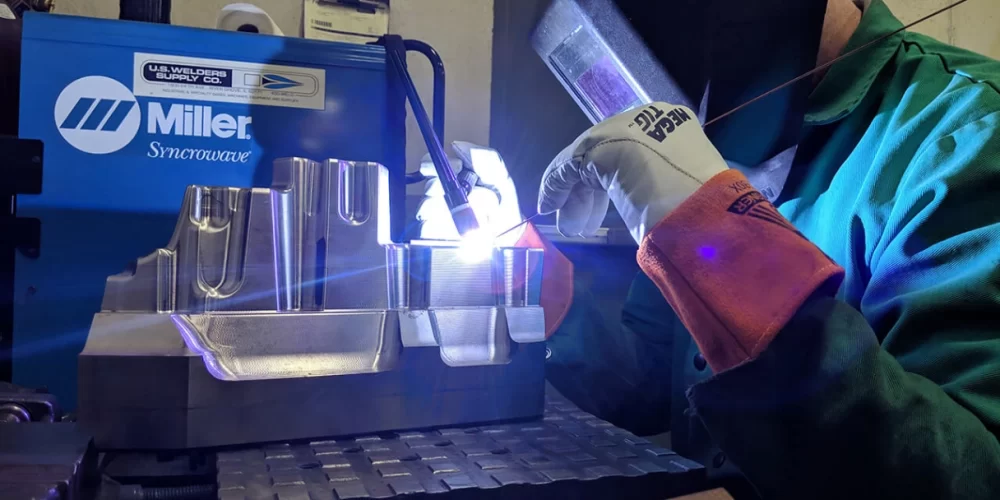

Once all maintenance, change orders or repairs have been completed, we properly stress-relieve and reapply any surface treatments. Our skilled team of mold-makers will assemble, leak-test and check all other functions to ensure that your tool will run properly when you receive it. Our goal is to return your tools to you in virtually new condition.

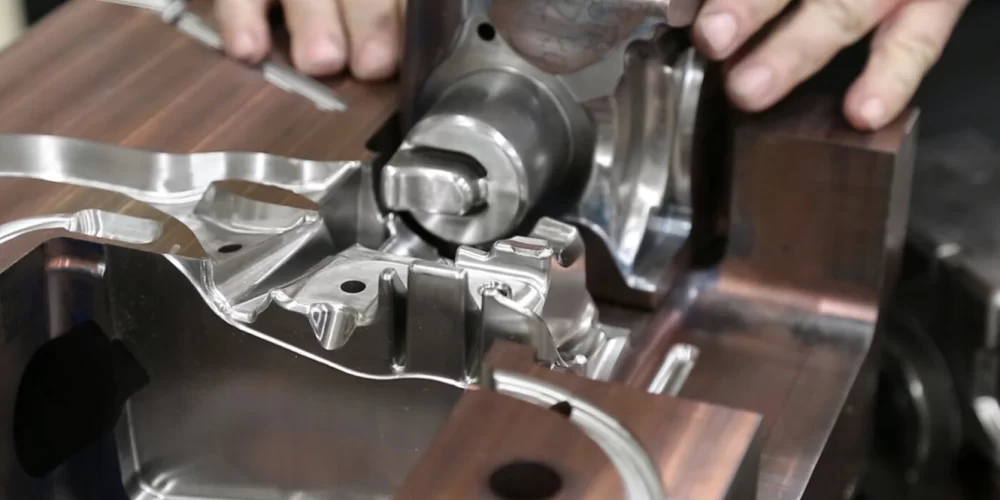

Our experienced staff is often called in to evaluate dies and molds that are running below expectations. Many times we find these tools have been built overseas or manufactured on a tight budget. We are able to recommend ways of either improving or modifying your current tooling, or coming up with an entirely new design to help eliminate your problem. No challenge is too complex for us, and we are happy to assist you regardless of who made your tooling. Our goal is to free you from the frustration of manufacturing problems so you can focus on what is important to you…..making parts and new business opportunities.

At Elba Tool, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling