Reducing machining times while improving quality.

Like most manufacturing businesses, we are always looking for ways to cut costs without sacrificing quality. So it was a welcome breakthrough when recent software and machining improvements allowed us to cut expenses by 15-20% and improve the quality of the finished product.

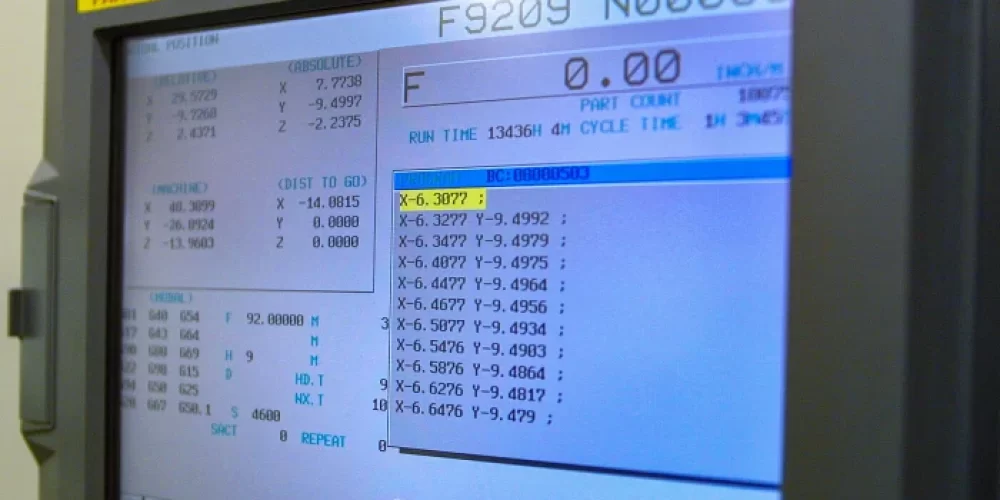

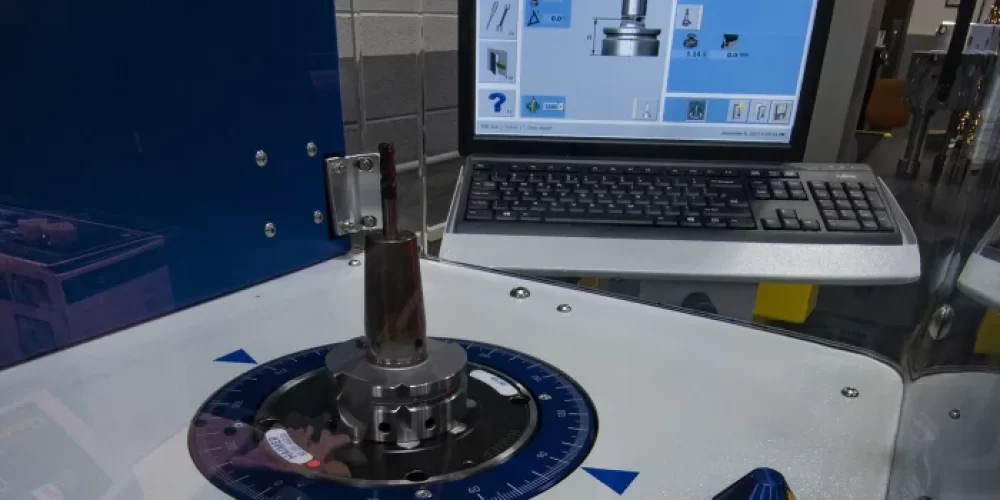

Recent upgrades in our CNC programming software and milling equipment have made a big difference in our process. With the latest advances in software and cutting technology, we keep improving the way we make our dies, molds, and parts. Combine that with the support and training we get from our suppliers, we can take full advantage of all these improvements and generate a tremendous amount of throughput.

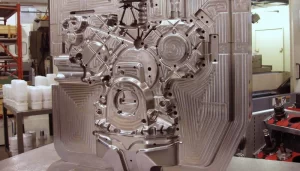

A job to produce a complex die cast die is a good case in point. The tooling was for a timing cover for a tractor engine. We were able to machine the entire die with no EDM’ing. Using this streamlined process saved us time and money and reduced errors at every step.

Milling everything in one setup saves man hours and improves accuracy. Also, EDM, if not done properly can stress the steel surface, potentially resulting in premature failure of the steel in die-cast applications. More machining and less EDM’ing means increased die life and castings.

We are continually evaluating and updating our CAD and CAM softwares to help improve our overall productivity. Without ongoing continual improvements such as these, we couldn’t have made the jump to efficiently machine larger parts and utilize our equipment to it’s fullest capacity. Old software takes too much time and makes too many mistakes. Upgrading was money well spent.

One advantage of our suite of state-of-the-art software is the collision checking feature. Using collision checking, programmers can optimize their cutting tool use without gouging the part. Every little bit of length on a small diameter cutter makes a big difference on finish quality, tool chatter, and tool life. Unattended machining frees the operator to do other work in addition. And when the program is done right, the part is good. No gouges, no problems, no worries.

Get Started

Innovation and technology means helping you increase productivity and profitability to remain viable in today’s global environment.

At Elba Tool, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling