Capabilities

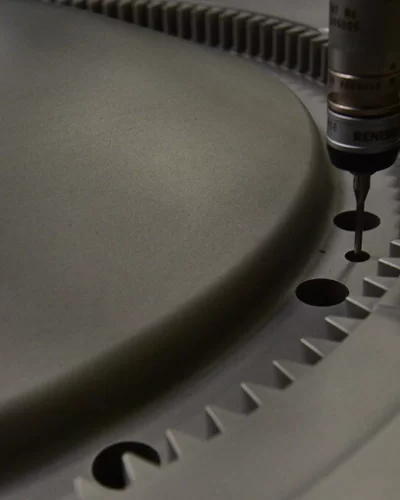

At Elba, concern for quality is deep in our DNA. Our team strives to meet quality standards that are among the highest in the industry. At the start of your project, our engineering department identifies targets that are dimensionally or functionally significant. These key specifications will be monitored continuously from start to finish.

We are constantly monitoring and checking parts and tooling dimensions. Issues that might affect the quality and function of the components we produce for you can be detected before they even come off the machine — and resolved before final inspections are made.

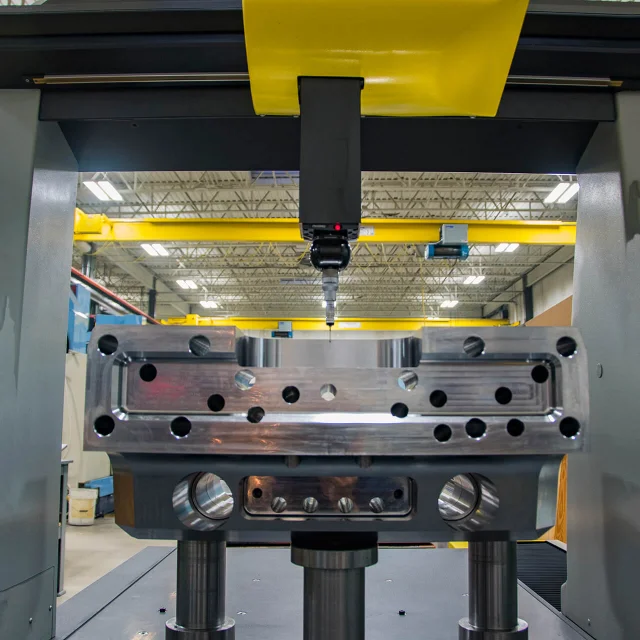

Acceptance testing is performed using our dedicated quality control equipment that is strategically located in our facility to handle larger and heavier parts. This equipment features the latest in testing technology, including a Brown and Sharpe CMM supported by a 3-ton hoist for larger and heavier parts.

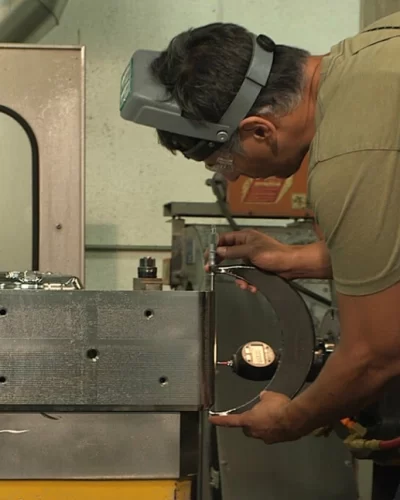

Precision machining, die-cast die making and mold building are extremely demanding tasks. It takes years for machinists and tool and die makers to learn and perfect their craft. At Elba, we are devoted to giving all team members the support and training they need to master the crucial skills involved in the work we do.

Our work environment is driven by the latest technology, yet our work ethic is inspired by traditional craftsmanship. We are proud that we receive virtually ZERO returns for dimensional errors.

Whether you are looking for precision-machined components, die-cast dies, plastic molds or other specialized machining services, the Elba team is at your service.

At Elba, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling.