Reduce Downtime And Extend Tool Life

Downtime constantly drains profits from die casting operations. What if there were a way to make dies last longer and perform better?

Die casting, known for its ability to create complex parts, comes with its challenges. Understanding and preventing defects is essential to creating seamless parts while reducing downtime and costs.

In this article, we’ll explore the common challenges die casters face with tooling wear– and explain why die longevity is critical for efficiency and savings.

The most important parts of the die casting process are choosing the right die material and ensuring proper operating conditions to get the most out of the tooling.

Here are the main factors that influence die life:

The casting temperature significantly impacts die longevity. Higher temperatures cause wear and thermal fatigue. For example:

Proper cooling, lubrication, and heating cycles minimize thermal stress and prevent heat check cracking. Consistent maintenance assures top die performance, assuring small issues don’t turn into an expensive failure.

Now that we’ve explored the factors that affect die longevity, let’s take a look at how precision engineering is the basis of high-performing die-cast tooling. Every step, from design to machining, plays a crucial part in enhancing durability. The more accurate the engineering, the longer the die will perform.

Die castings require detailed tolerances to prevent inaccuracies and maintain performance. Even the smallest variation can lead to fatigue, misalignment, or premature failure.

Tolerance standards depend on several factors, including:

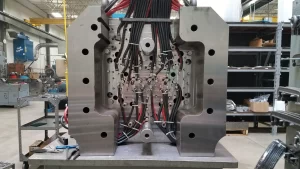

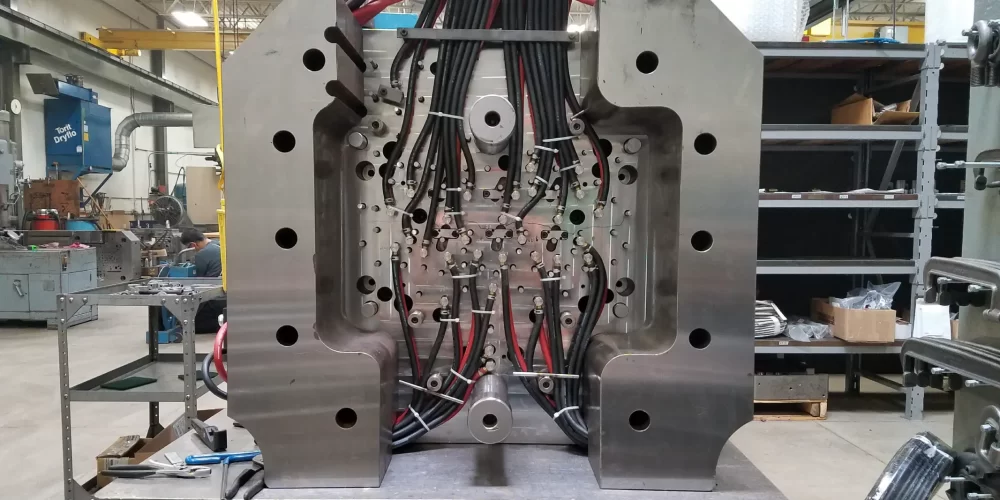

Advanced machining techniques, such as CNC milling and EDM, allow each die to meet excellent precision, resulting in superior die quality and consistency.

Precision-engineered cooling systems regulate temperature changes during casting, significantly reducing the possibility of thermal fatigue and preventing heat-related damage.

At Elba, precision isn’t just a word. It’s a promise. Our engineers analyze each project with detail, using cutting-edge technology to craft dies that perform better and last longer. Our commitment to detail delivers fewer production interruptions, lower maintenance costs, and greater efficiency for our customers.

To maximize the life of die cast tooling, die casters must focus on reducing wear and enhancing durability by:

By following these practices, die casters can extend tooling life, reduce costs, and improve production efficiency.

At Elba, we specialize in building high performing die-cast tooling for leading automakers and manufacturers. We understand that die longevity is essential for cost-effective production. Here’s how we achieve it:

When a custom die caster faced high scrap rates and costly impregnation due to leaky castings, Elba partnered with a dedicated team of vendors to find a solution. Through precision engineering and advanced technology, we improved their production process and reduced costly defects.

Want to know how we did it? Read the full case study here.

Get Started

Let’s increase your productivity and profitability today.

Whether you are looking for precision-machined components, die-cast dies, plastic molds or other specialized machining services, the Elba team is at your service.

At Elba, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling.