Reducing customer scrap rates through advanced technology

A custom die caster needed help producing a high-volume front cover casting, that was plagued with high scrap rates and impregnation costs.

Elba Tool and Magma were contacted to propose modifications that would reduce or eliminate problems caused by excessive porosity.

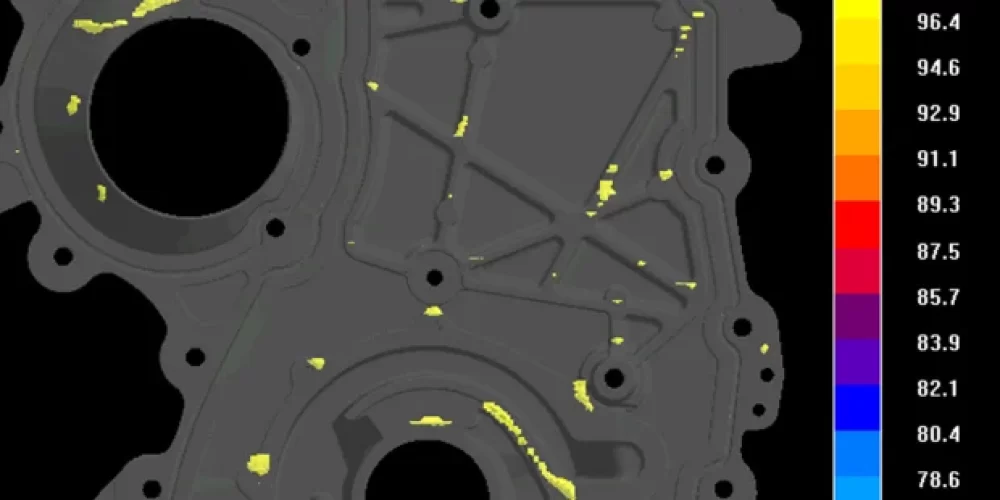

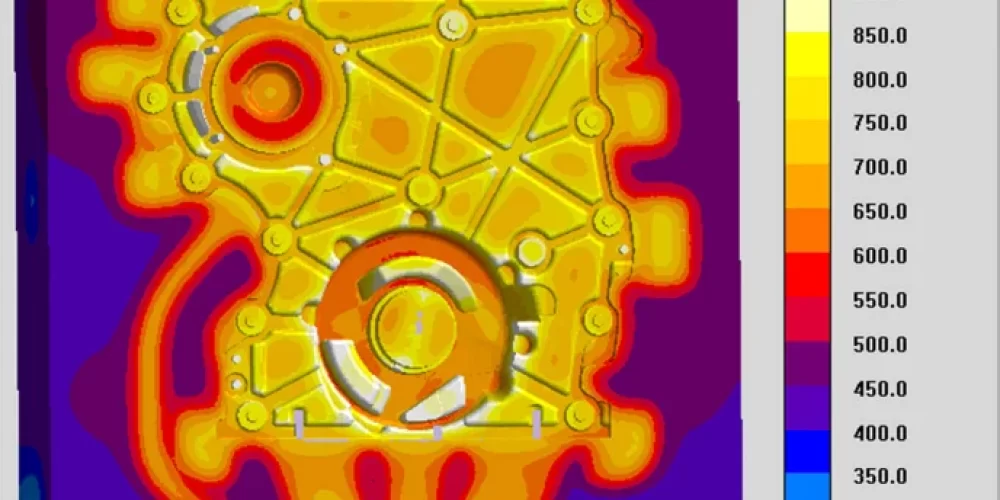

After several iterations of analyses the shrinkage porosity was significantly reduced. Part geometry modifications would be required to eliminate or reduce the remaining porosity.

Elba Tool modified the part model and 3D part geometry was submitted for approval by OEM prior to proceeding

Running process simulations again showed a significant reduction in porosity and hot spots. Although not completely eliminated, analysis of the data showed the results to be more than acceptable

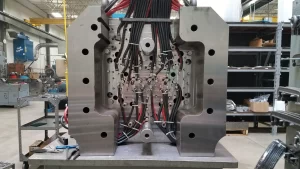

Dies were redesigned with new casting and gating geometry and built accordingly. Cooling was placed strategically, and manifolds with valves were added to the tool to allow adjustments as conditions dictated.

Initial sampling showed the following results:

A strategic partnership with Elba Tool and it’s team of qualified vendors helped achieve superior results through technology and expertise allowing our customer to focus on production.

Elba Tool has the knowledge and working relationships with vendors in place to help you achieve success. If you have a problem that has been difficult to solve, or don’t have the time to address it, let us know and we can help you increase efficiency and profitability.

Get Started

Let’s increase your productivity and profitability today.

Whether you are looking for precision-machined components, die-cast dies, plastic molds or other specialized machining services, the Elba team is at your service.

At Elba, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling.