Capabilities

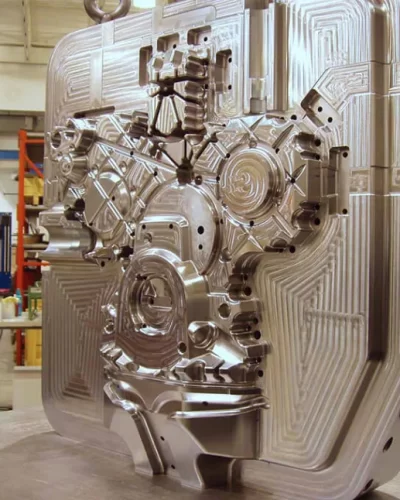

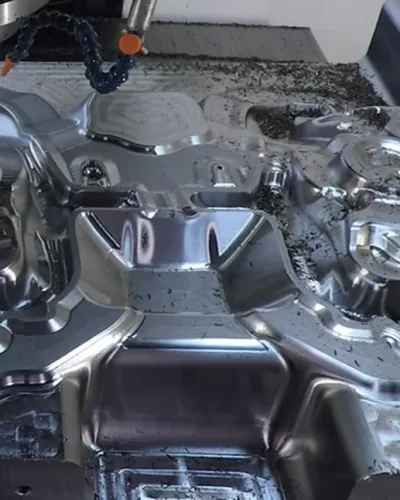

Whether we’re machining a custom part out of billet, or making a replacement component for a die or mold, having the right equipment for the task is essential. Our advanced CNC equipment allows us to custom machine components with superior fit and finish.

In crafting your components, we implement highly efficient milling strategies and tooling technologies that make the most of our machining center’s capabilities. We have the advanced capacities needed for lights-out production, which can reduce lead times and costs for you. Whether we are working with softer, non-ferrous materials or hardened steels, our machining centers have the power and rigidity to remove material quickly and efficiently, regardless of the cutting conditions.

Our skill and experience in CNC machining enables us to deliver the highest level of quality for you. Magnetic work holding gives us the flexibility to fixture your parts efficiently. Laser tool presetting in the machine allows us to adjust offsets with ultimate precision before any cutting tool touches your parts. The higher speeds and feeds of our machining centers help us work rapidly AND accurately, translating your virtual designs into components and tooling that meet or exceed your most stringent requirements.

To ensure that our equipment is operating at factory specs or better, all machines are laser-calibrated on a regular basis, tooling and holders are balanced and dedicated to machining centers to maximize spindle life, and frequent preventative maintenance is done to ensure that everything is working at peak performance. This all translates to less downtime and greater production capacity.

Whether you are looking for precision-machined components, die-cast dies, plastic molds or other specialized machining services, the Elba team is at your service.

At Elba, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling.