Capabilities

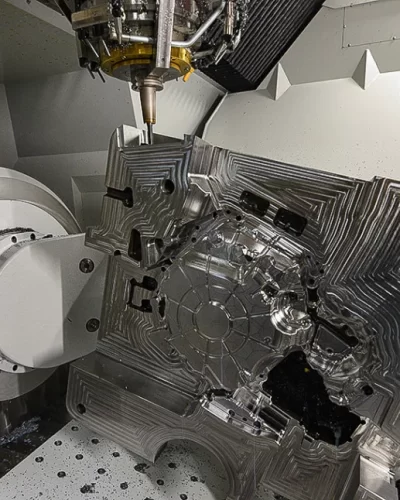

For more than a decade, we have used our advanced 5-axis capabilities to craft complex parts and tooling components to our clients’ exact specifications.

These sophisticated machines let the cutting tool approach the workpiece from many different directions, enabling our machinists to create virtually any shape with intricate undercuts and angles, often in a single setup. Minimizing the number of setups and machine transfers reduces downtime and shrinks the chance for errors, ensuring consistent accuracy and faster turnaround times.

The additional axes offered by our equipment allow for a broader use of milling strategies, often increasing reach without increasing the length of the tool used. Shorter tools produce higher cutting speeds with fewer tool vibrations, which means greater precision and better surface finishes. We are able to reduce production time by machining areas that would normally be handled with EDM equipment (a much slower process).

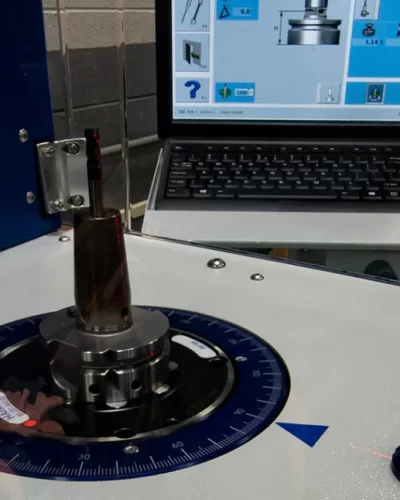

Our Roeders ultra-high-speed 5-axis mill is a prime example of our investment in high-tech machinery that provides superb precision and speed. Its powerful linear motors provide a consistent feed rate that dramatically improves turnaround times. The powerful, high-torque spindle allows us to tackle a wide variety of soft and hard materials using a wide range of cutting tool sizes. The mill is ultra-precise, holding extremely tight tolerances. Even with the mill’s large work envelope, the machine is thermally monitored for amazingly accurate repeatability.

A 41-Inch Work Envelope*

A 47-inch work envelope*

Whether you are looking for precision-machined components, die-cast dies, plastic molds or other specialized machining services, the Elba team is at your service.

At Elba, we are a team of seasoned professionals, implementing state-of-the-art technology, delivering the most challenging parts and tooling.